What is a Vibratory Feeder?

Figure 1

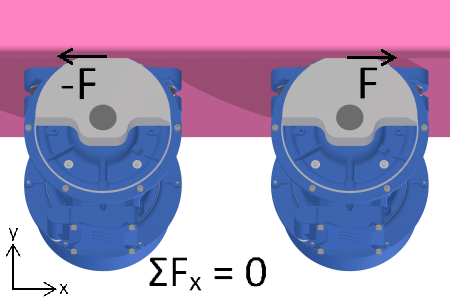

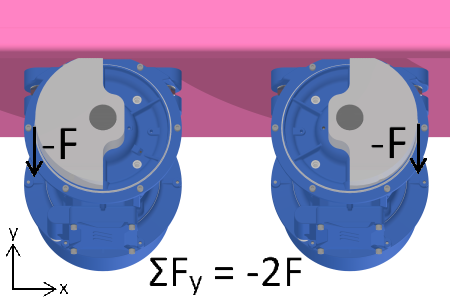

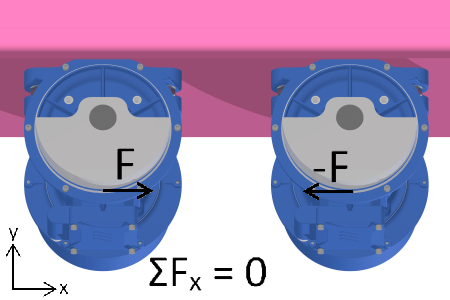

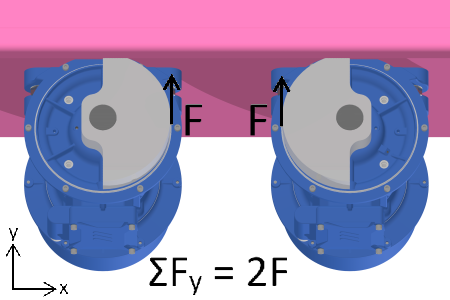

Vibratory feeders utilize two high speed eccentric rotating mass (ERM) motors to create a vibratory motion which conveys material forward. The two ERM motors are mounted parallel to each other and spin in opposite directions. The rotation of these motors will naturally synchronize to each other. A force is generated tangent to the direction of motion of the rotating mass. (See figure 1)

Because the weights are moving in opposite directions and with synchronized motion, the forces in the x-direction cancel each other out, while the forces in the y-direction add together. The result is a quick back-and-forth motion of the feeder, which throws the material forward and disperses the material evenly for a clean, consistent flow to downstream equipment.

Vibratory feeders can be an important addition to provide efficiency and consistency to a properly operating processing system.