What is a Steel-Belt Conveyor?

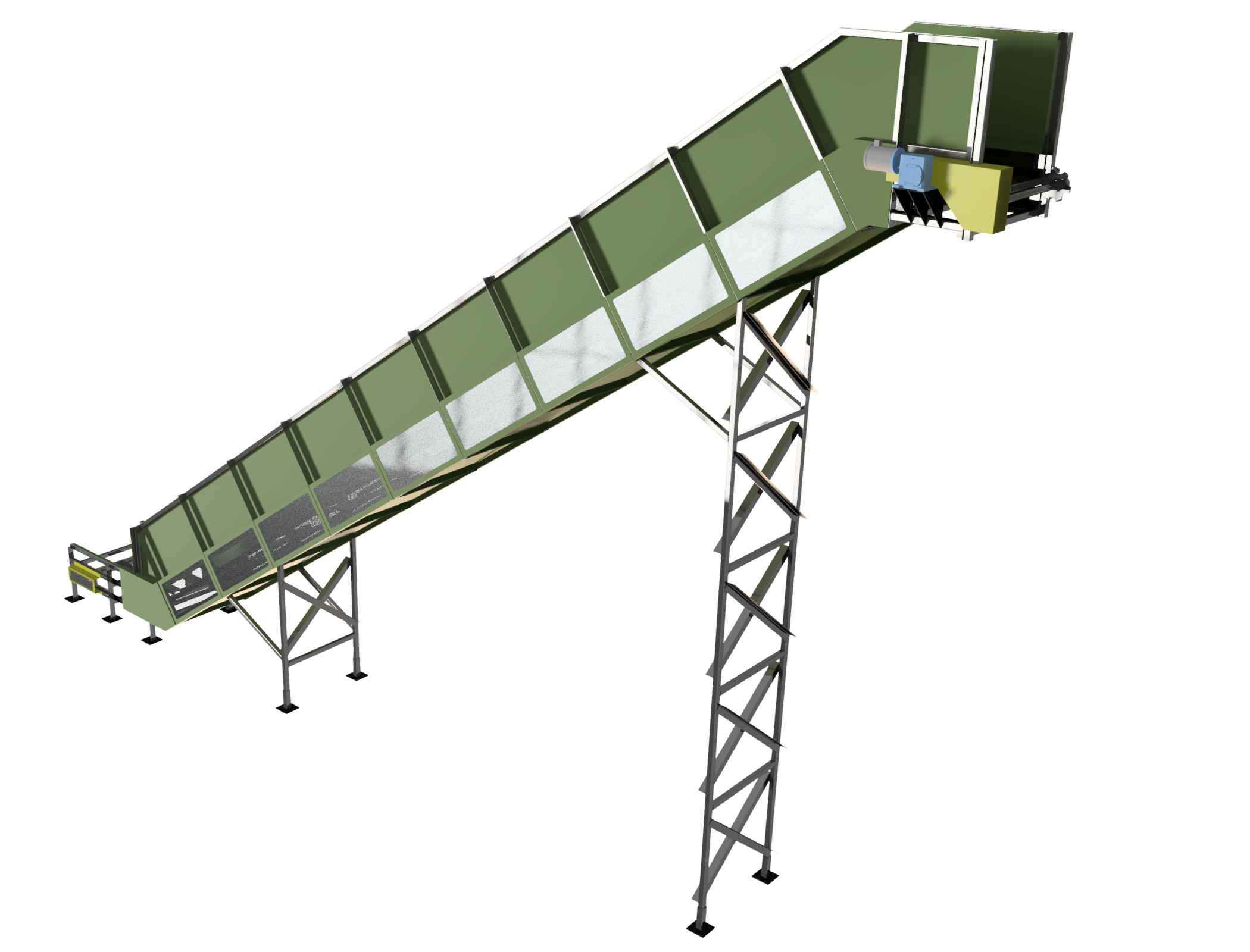

Steel-belt conveyors are the most durable conveyor type to use when sharp-edged or puncture-causing materials are being conveyed. Such material includes scrap metal and electronics. The conveyor has hinged steel-belting to carry the material and chains attached to either side of the belting handle the belt’s pull-loading and tracking functions.

Steel-belt conveyors are often required for bulk feeding because of their increased durability over rubber-belt conveyors. Steel cleats attached at fixed intervals on the belt can provide metering of material as it is conveyed up an incline since each cleat will stop the sliding of only a certain height of material (also known as the burden height) and the additional material will cascade back down the belt.

There are a variety of different types of steel belts that are utilized based on the material being conveyed. Consultation with the manufacturer should be made to ensure the belting and conveyor are properly sized for your application.