What is a Hammermill Shredder?

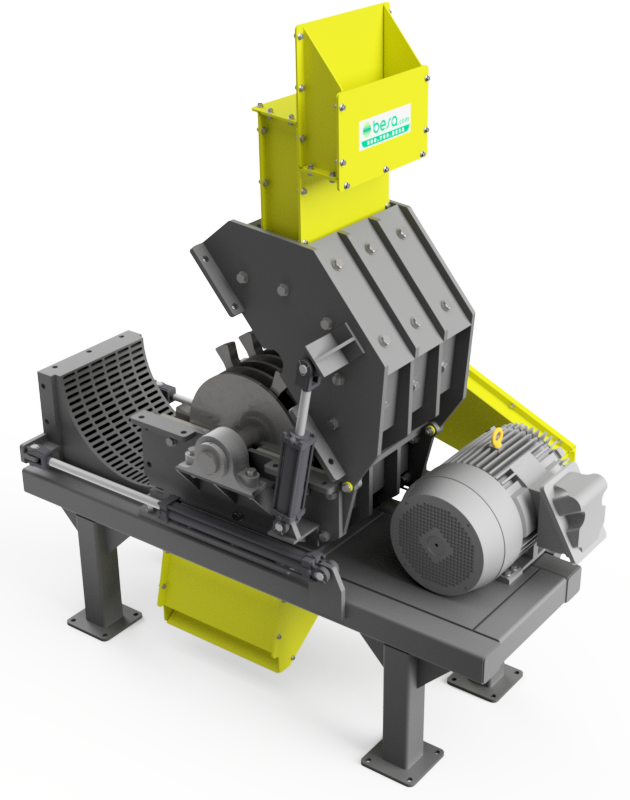

Hammermill shredders are impact shredders. Hammers rotating at high velocities strike the material causing it to fragment upon contact. Material is struck many times until the desired size reduction is achieved and the shredded material can pass through holes in a fixed screen located under the cutters. The size of these screen holes controls the size of the shredded material.

Industrial hammermills are typically used when material density is too high to economically shred in low rpm shear-style shredders. Since these shredders fragment material, more fines will be created than other shredding methods and dust control is often required. Additionally, noise levels will be considerably higher than other methods due to the violent nature of the impact-shredding process.

The type of material, production, and shred-size requirements need to be considered when sizing a hammermill. Serviceability, maintenance and operational costs also need to be considered.